Diaphragm synchronous stretching machine

Diaphragm synchronous stretching machine

What is a diaphragm synchronous stretching machine?

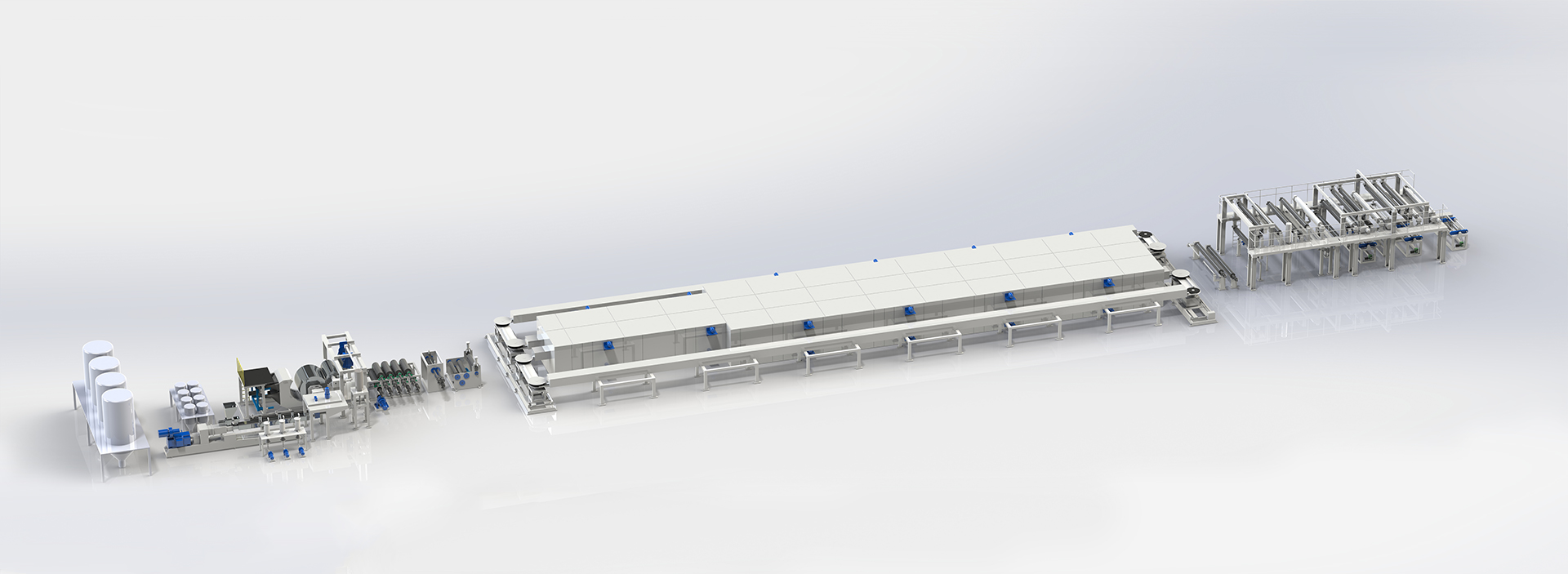

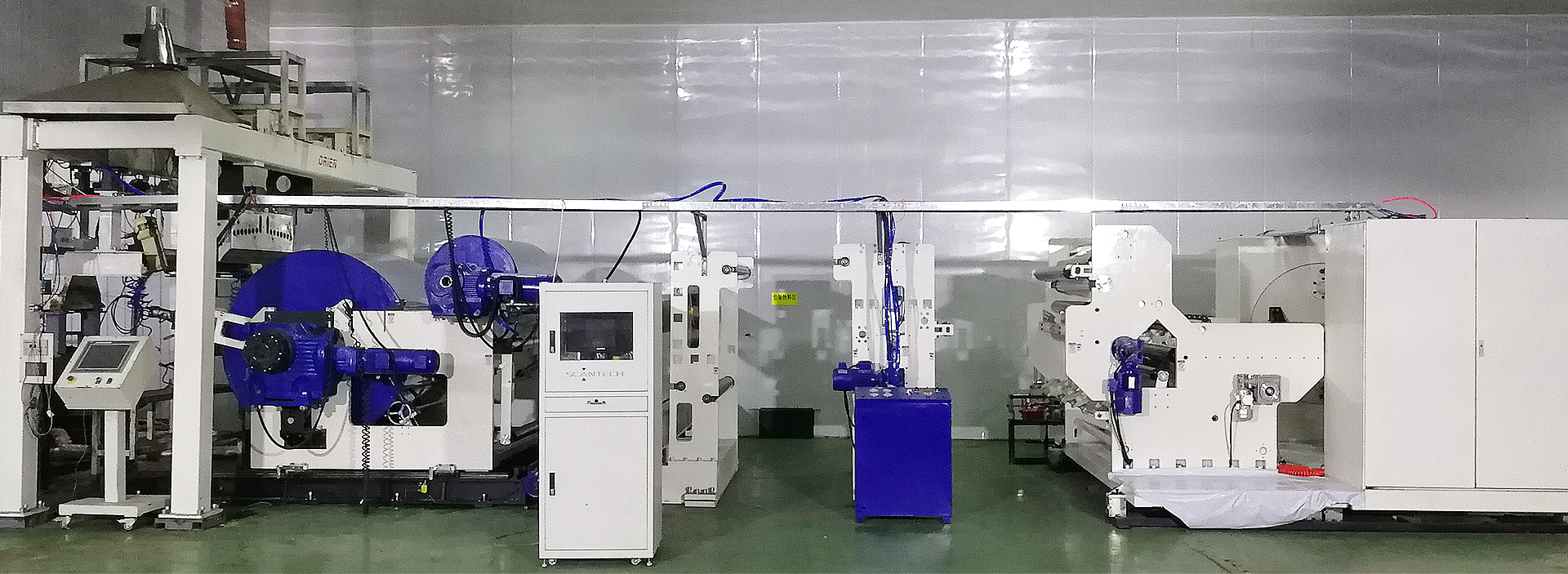

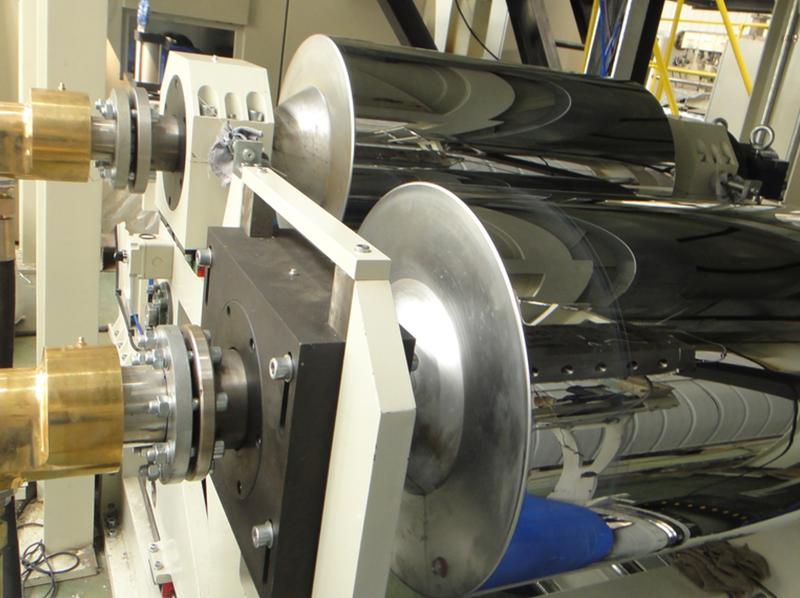

Diaphragm synchronous stretching machine, including single station unwinding machine, synchronous stretching machine, post-stretching trimming unit, waste edge online recycling system, 1 traction machine after stretching, automatic cutting and winding machine after stretching The electric control system, the crimping device and the clip cooling system are installed on the bottom plate of the track device, and the open clamping device is connected with the inlet and outlet of the track device. The diaphragm synchronous stretching machine fundamentally changes the previous polymer film to be stretched successively. The traditional process makes it realize synchronous stretch forming in the equipment, solves the special processing technology problem of polymer materials which are difficult to stretch the orientation successively, has simple process flow, reasonable structure, low comprehensive investment cost of equipment, and maintenance cost. low. Synchronous stretching systems have been used to produce high-end films, including optical grade films, ultra-thin films, and many other films with extremely stable physical properties. Since the film does not come into contact with any of the rolls during the stretching process, the optical properties and surface properties of the synchronously stretched film have a qualitative leap compared to the conventional two-step drawing process.

What is the use of the diaphragm synchronous stretching machine?

Can be used to produce a variety of different types of film, including shrink film, high barrier film, low heat seal film, ultra film, optical film and BOPP, BOPET, BOPE, BOPA and BOPLA film. Synchronous stretch film has high added value and large profit margin. Which synchronous stretching technology is used by film manufacturers is the key to determining the cost of such high-end film processing. At present, there are several technologies on the market that can simultaneously stretch the film in both directions (longitudinal and transverse), namely a double bubble process, a linear motor driven synchronous stretching technique and a mechanical synchronous stretching technique. Among them, the double bubble process is the oldest technology, but this technology can not produce high-end film. Linear motor-driven stretching systems cannot be widely used in this field because of the large investment, the high operating costs, and the limitations in terms of process. Only the mechanical synchronous stretching technique can significantly improve the film properties under the condition that the cost is not increased much.

Membrane synchronous stretching machine equipment composition:

Diaphragm synchronous stretching machine, including single station unwinding machine, synchronous stretching machine, post-stretching trimming unit, waste side online recycling system, 1 traction machine after stretching, automatic cutting and winding machine after stretching Electronic control system.

Qingdao Ou Rui Taike Plastic Machinery Co., Ltd. Diaphragm Synchronous Stretching Machine Features:

1. High reliability and low maintenance cost

The simple design of the synchronous stretching machine makes it highly reliable and low in maintenance cost. Linear motor-driven synchronous stretching systems with unusually complex linear motors, because of the need to cool linear motors operating in high temperature environments, additional roller bearings guide all chain clip conveyors on the track, as well as the need for numerous frequency converters and additional The transformer eliminates the sway effect, resulting in reduced reliability, long downtime, expensive spare parts, and high service requirements.

2. Process advantages

Synchronous stretching machine of Qingdao Ou Rui Taike Plastic Machinery Co., Ltd. can dynamically and continuously stretch, with a width of 2000mm-4600mm. The special structural design solves the problem that the vertical stretching is not adjustable, and the horizontal adjustment is 2 times minimum. Qingdao Ou Rui Taike Plastic Machinery Co., Ltd. Synchronous stretching machine has a chain clamp on the film side of each scale joint. Each chain clamp stretches the film in the longitudinal direction, and only a small amount of the film edge to be trimmed is not stretched, thereby maximizing the stretching, and the number of film breakage is small, and the bowing effect affecting the film quality is also greatly reduced. . In contrast, the linear motor system has a driven chain clamp conveyor and two non-driven chain clamp conveyors. In fact, the true physical longitudinal stretching is performed only by the driven chain clamp conveyor, while the non-driven chain clamp conveyor does not have a longitudinal stretching function, which results in uneven film properties, increased number of film breaks, and no pull. The spacing between the stretched edges increases and the bowing effect increases.

Qingdao Ou Rui Taike Plastic Machinery Co., Ltd. Synchronous stretching machine is very suitable for low-speed production, such as it is often used in special thick film production. Structurally, there is no limit to the speed of the synchronous stretching machine. Linear motor systems have their limits at low speeds because the system becomes very unstable at too low a speed.

3. Low energy consumption advantage

The significant reduction in investment costs and energy consumption is another important advantage of the synchronous stretching system driven by Qingdao Ou Rui Taike Plastic Machinery Co., Ltd. and linear motor. Linear motor technology consumes a lot of energy, mainly caused by copper and inverter losses. This energy must be transferred from the chain clamp system to a cooling water system. This makes electrical energy, an unpredictable energy source, a high risk factor. The synchronous stretching machine system of Qingdao Ou Rui Taike Plastic Machinery Co., Ltd. has great advantages in this respect.